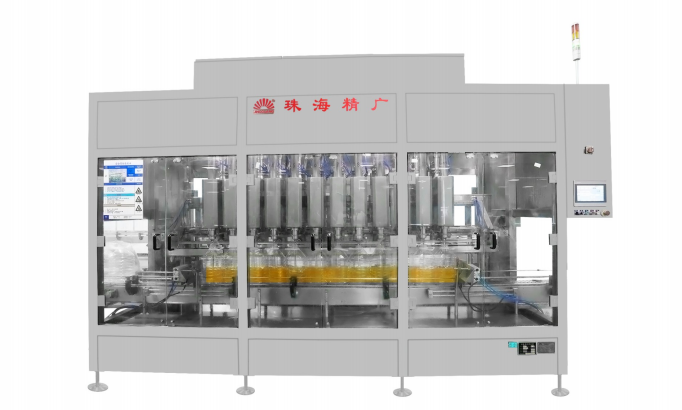

Before filling, the upper weighing filling machine counts and judges whether there are all bottles at each filling station by the sensor on the conveyor belt. If the conditions are met, the filling starts. If the conditions are not met, the filling valve will not start.

During the filling process, in order to obtain excellent filling accuracy, the electronic gauge continuously monitors the filling volume during the filling process. Close the filling valve at the end of filling; Send a signal to inform the station of the unqualified bottle and remind the operator to deal with the unqualified bottle.

The weighing type filling machine also has the integrated automatic check function of electronic weighing, which can evaluate the actual filling amount of the previous filling after each filling, compare it with the preset target value of the filling menu, and adjust the filling amount accordingly in the next working cycle. In the net weight filling mode, the actual filling volume can be adjusted automatically even if the actual weight of the filling result is within the preset weight deviation range. This feature, called self-calibration, allows product filling temperature, product viscosity, and filling pressure to maintain a stable filling volume result as they change during the job.