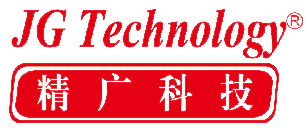

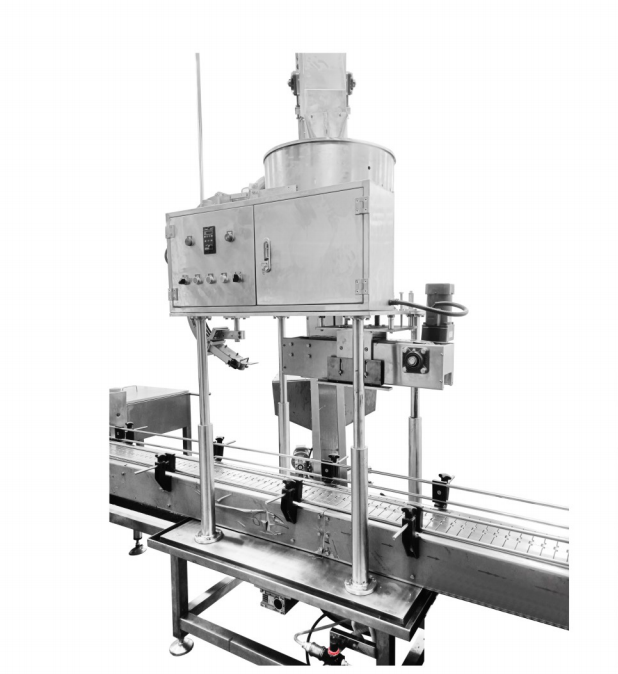

Equipment model: JG-16LX

Production capacity: combined with filling line

Main components: lid lifter, centrifugal capping machine, pneumatic centralizing system, photoelectric induction system, photoelectric induction system, capping machine

Process: The lid lifter supplies the required covers in a fixed amount. The hopper of the capping machine is equipped with a cap amount detection sensor. When the cap amount in the hopper of the capping machine is less than what is required for operation, it will automatically lift the lid and stop the machine when the cap amount is more, so as to avoid the excessive friction of the lid when it is being centrifuged for capping; The cover conveying and cover hanging rails formed by precision wire cutting in the track section can prevent track vibration or collision from easily causing track deformation, which affects the cumbersome shunting and the efficiency of cover hanging. The track is equipped with a missing cover detection and automatic alarm function, and a reverse cover removal and collection function to ensure that the reverse cover does not enter the cover hanging section.